CAROLINE DELBERT

Mechanical engineers from Johns Hopkins University in Baltimore have found a new way to build body armor with a lightweight elastomer material that relies on a complex liquid crystal structure. The resulting armor is “lighter, stronger, and reusable,” according to the university’s press release. That could be a game-changer in the highly deformable world of body armor.

Sung Hoon Kang—senior author of the new paper, published in February in the journal Advanced Materials—is part of the tantalizingly named Hopkins Extreme Materials Institute (HEMI), established in 2012 to study “science associated with materials and structures under extreme conditions and demonstrating extreme performance.” Its projects are funded by organizations like the U.S. Department of Energy and the National Science Foundation, with areas of study including things like how materials behave in Earth’s mantle.

It’s easy to see how Earth’s mantle is extreme, with some of the highest temperatures and pressures on the planet. Body armor is a different application, but something that is still very extreme: absorbing gunshots, for example, and spreading that energy out in a way that does not harm the wearer is no small feat. “We are excited about our findings on the extreme energy absorption capability of the new material,” Kang says in the statement.

The idea of a material that can outperform today’s helmets and car bumpers piqued Kang’s curiosity. One of the major areas for improvement is deformation, which is the way the force of an impact presses material way out of shape. Think of a car’s “crumple zone,” which is literally designed to collapse to absorb impact; you’re not exactly “reusing” that portion of the car afterward, especially in higher-speed crashes.

“Many helmet and impact-absorbing materials dissipate energy through inelastic mechanisms, such as plastic deformation and fracture and fragmentation. However, these materials can become permanently damaged after one-time usage and are not suitable for repeated use,” the researchers write.

So if the non-reusable mechanisms are inelastic—which makes sense, the opposite of elastic and therefore unable to “bounce back”—how do we do things differently? This is where the idea of metamaterials comes into play. A metamaterial is something carefully engineered on the micro-scale to have properties that a simple layer of plywood or metal would not have. The goal is to build better functionality starting at the atomic level.

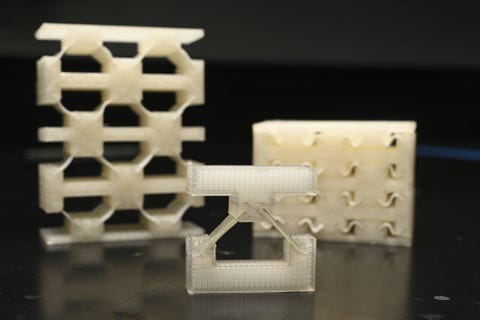

John Hopkins University’s new shock-absorbing material.

WILL KIRK / JOHNS HOPKINS UNIVERSITY

The researchers explain that their key here is something called “elastic buckling instabilities,” which you can think of like a kind of atomic-level bounce. Think of a big spring, which buckles under pressure, but then pushes right back into shape. The idea of buckling needn’t be a one-way deformation that permanently distorts the material. It can store up energy that is re-released in order to “bounce” the material back to its true form. “This structural energy trapping mechanism is scalable and reversible, which makes the architected material reusable,” the researchers explain.

In experiments, the team made metamaterials called liquid crystal elastomers (LCEs). These materials spread impact around and dissipate energy in an ideal way for the microstructure needed in a body armor design. “LCE-based architected materials may present many promising opportunities for energy-absorbing metamaterials for impact protection and damping applications,” the team explains. When tested, the material held up well to repeated impacts from objects weighing between four and 15 pounds at up to 22 miles per hour.

No comments:

Post a Comment